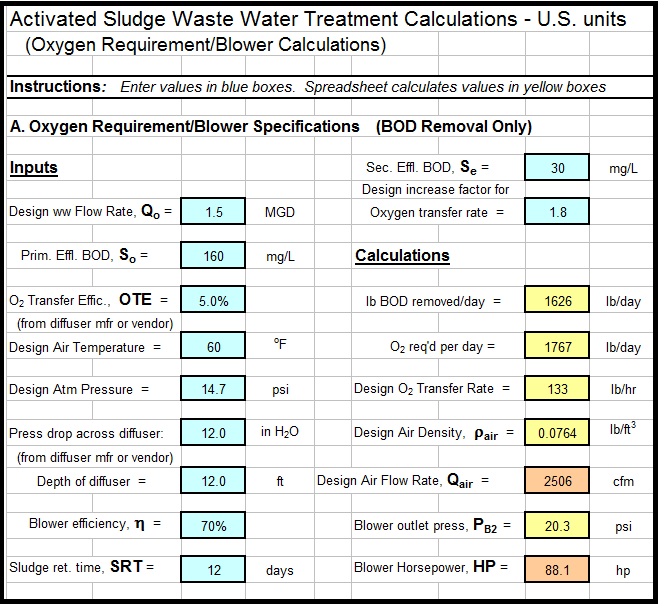

Where to Find a Spreadsheet to Calculate Oxygen Requirement Activated Sludge Process

To obtain a spreadsheet to calculate oxygen requirement activated sludge process, click here to visit our spreadsheet store. For use in calculating oxygen requirements and blower specifications, you can buy a convenient spreadsheet to calculate oxygen requirement activated sludge for a very reasonable price. This spreadsheet will calculate the oxygen requirement and blower specifications for BOD removal or for BOD removal and nitrification for specified wastewater flow and characteristics and diffuser characteristics, in either U.S. or S.I. units. Read on for information about Excel spreadsheets that can be used to calculate oxygen requirement activated sludge process parameters.

Oxygen Requirement Activated Sludge Background

The theoretical oxygen requirement for BOD removal can be approximated as ranging from 0.90 lb O2/lb BOD removed at an SRT of 5 days to 1.3 lb O2/lb BOD removed at an SRT of 20 days. This leads to the equation:

O2 requirement in lb/day = 0.90 + [(SRT – 5)/(20 – 5)](1.3 – 0.9)(lb/day BOD removed)

A design increase factor (safety factor) is typically multiplied times the calculated oxygen requirement to get the design oxygen transfer rate. The design oxygen transfer efficiency and the air density at design conditions can then be used to calculate the design air flow rate. The blower horsepower can then be calculated from the following equation:

Blower hp = (Qair)(ΔP)/(229*η)

Where:

- Qair is the air flow rate in cfm to be delivered by the blower

- ΔP is the pressure rise across the blower in psi = outlet pressure – inlet pressure

- η is the blower efficiency

If oxygen is to be provided for nitrification as well as BOD removal, then additional calculations are needed to estimate the oxygen requirement for nitrification.

Example Spreadsheet to Calculate Oxygen Requirement Activated Sludge Process

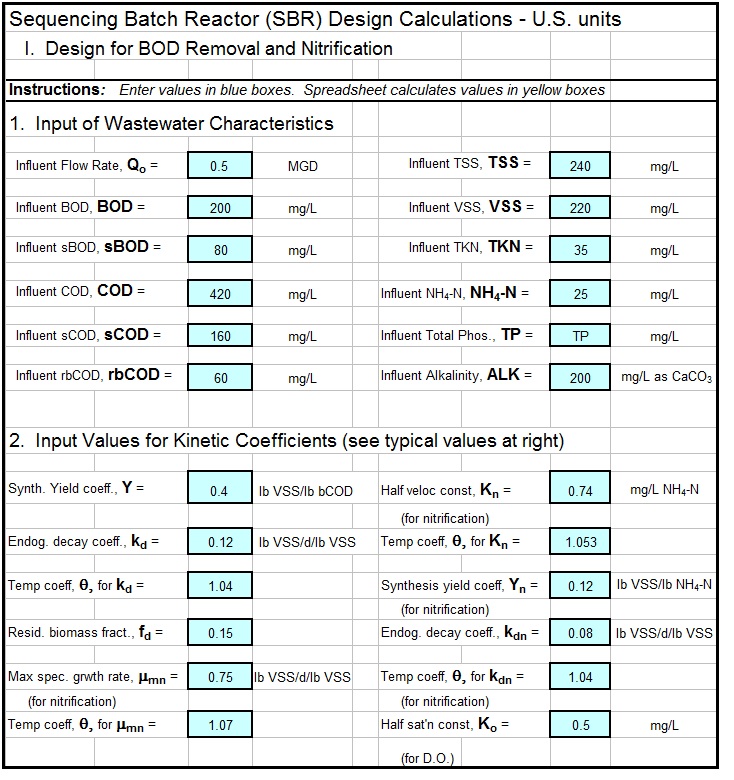

A spreadsheet to Calculate oxygen requirement activated sludge process is partially shown in the image below. It can be used to calculate the oxygen requirement and blower specifications for an activated sludge wastewater treatment system. This Excel spreadsheet, as well as others for wastewater treatment calculations, is available in either U.S. or S.I. units for a very reasonable price in our spreadsheet store.

References:

- Bengtson, Harlan H., “Activated Sludge Oxygen Requirement,” an online blog article.

- Bengtson, Harlan H., “Activated Sludge Calculations Spreadsheet: Aeration Tank Calculations,” an Amazon Kindle e-book.

- Bengtson, Harlan H., “Biological Wastewater Treatment Process Design Calculations,” available as a paperback book or Amazon Kindle e-book