Where to Find an EBPR A2O Design Calculations Spreadsheet

To obtain an EBPR A2O Design Calculations Spreadsheet, click here to visit our spreadsheet store. This Excel spreadsheet is intended for making design calculations for pre-anoxic denitrification and enhanced biological phosphorus removal in a CMAS (completely mixed activated sludge) system. You can buy a convenient EBPR A2O Design Calculations Spreadsheet for a very reasonable price. It is available in either U.S. units or S.I. units. Read on for background information about EBPR A2O Design Calculations.

Background for an EBPR A2O Design Calculations Spreadsheet

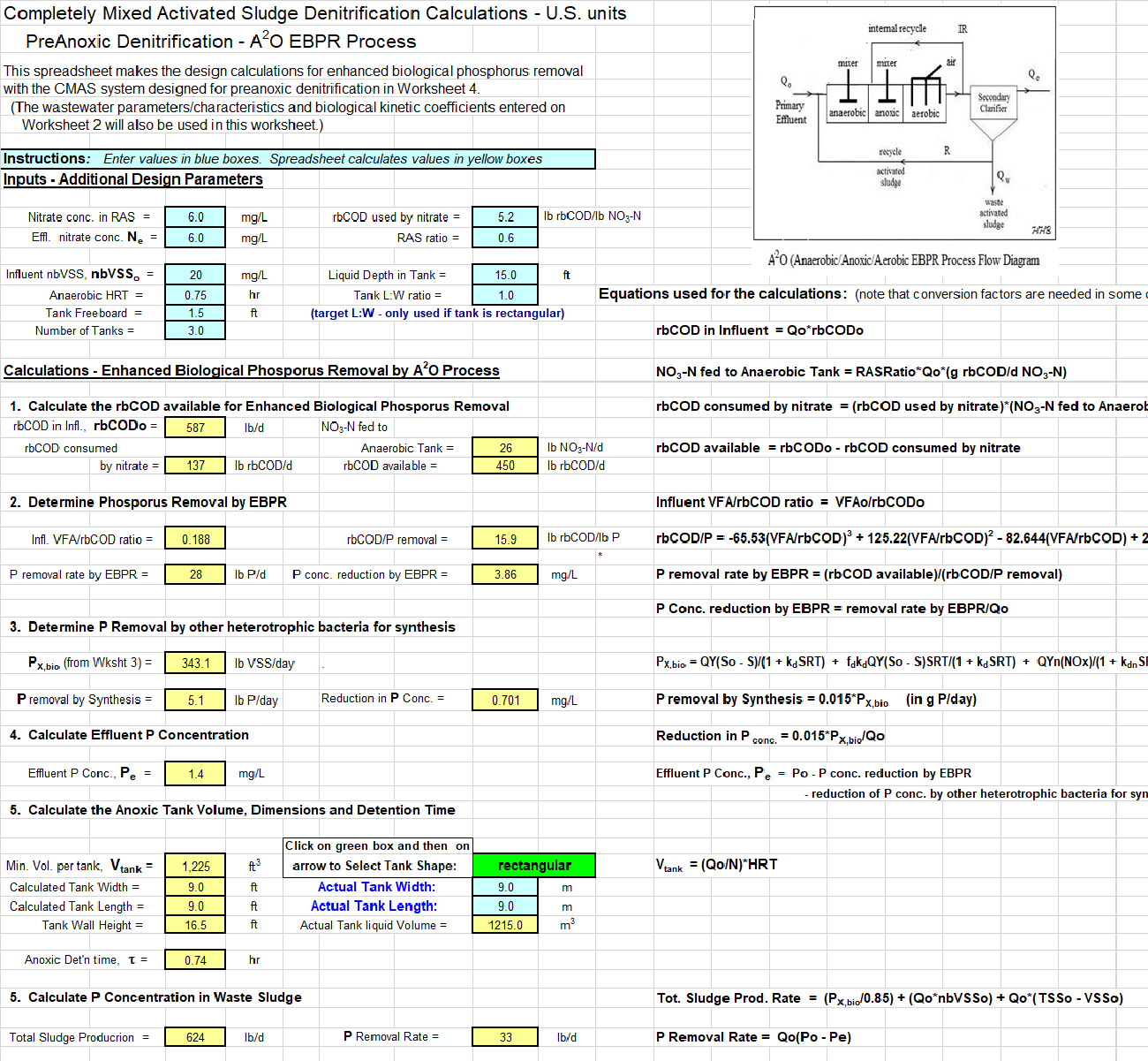

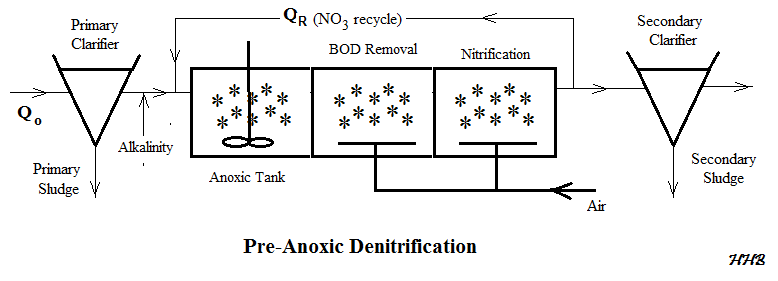

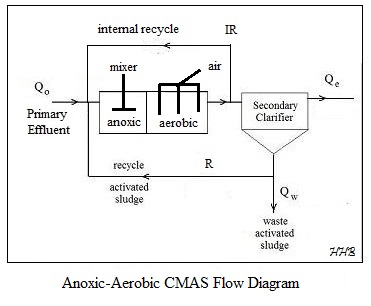

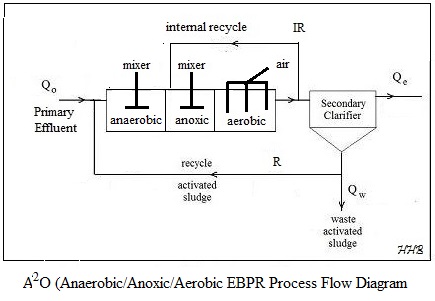

Enhanced Biological Phosphorus Removal can be carried out with the A2O (Anaerobic, Anoxic process, as shown in the diagram below.

The primary effluent goes first to an anaerobic tank, then to an anoxic tank and then to the aerated activated sludge tank. The recycle flows include an internal reycle (IR) flow from the aeration tank effluent to the anoxic tank, and recycle activated sludge from the secondary clarifier underflow to the anaerobic tank.

The primary effluent goes first to an anaerobic tank, then to an anoxic tank and then to the aerated activated sludge tank. The recycle flows include an internal reycle (IR) flow from the aeration tank effluent to the anoxic tank, and recycle activated sludge from the secondary clarifier underflow to the anaerobic tank.

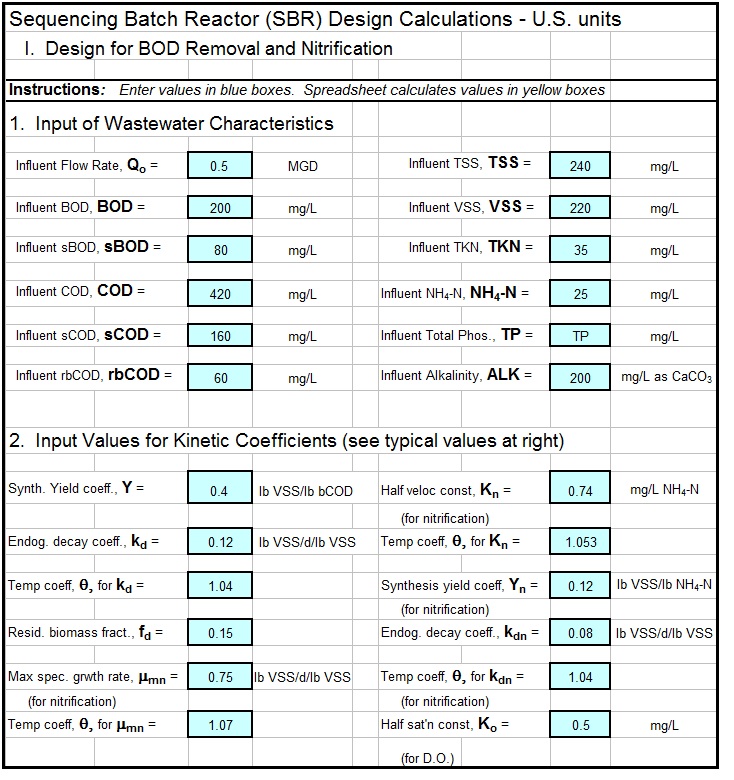

Example EBPR A2O Design Calculations Spreadsheet

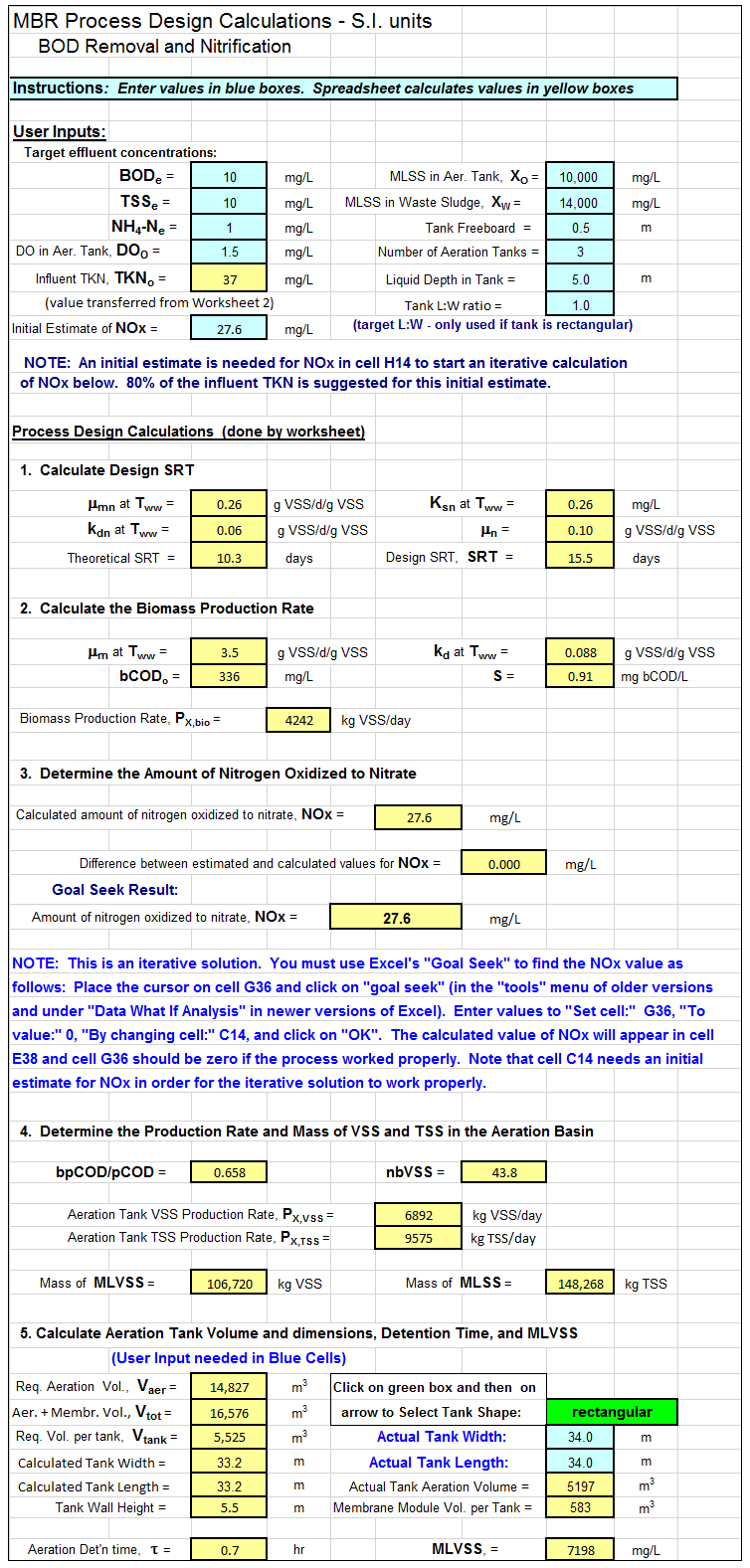

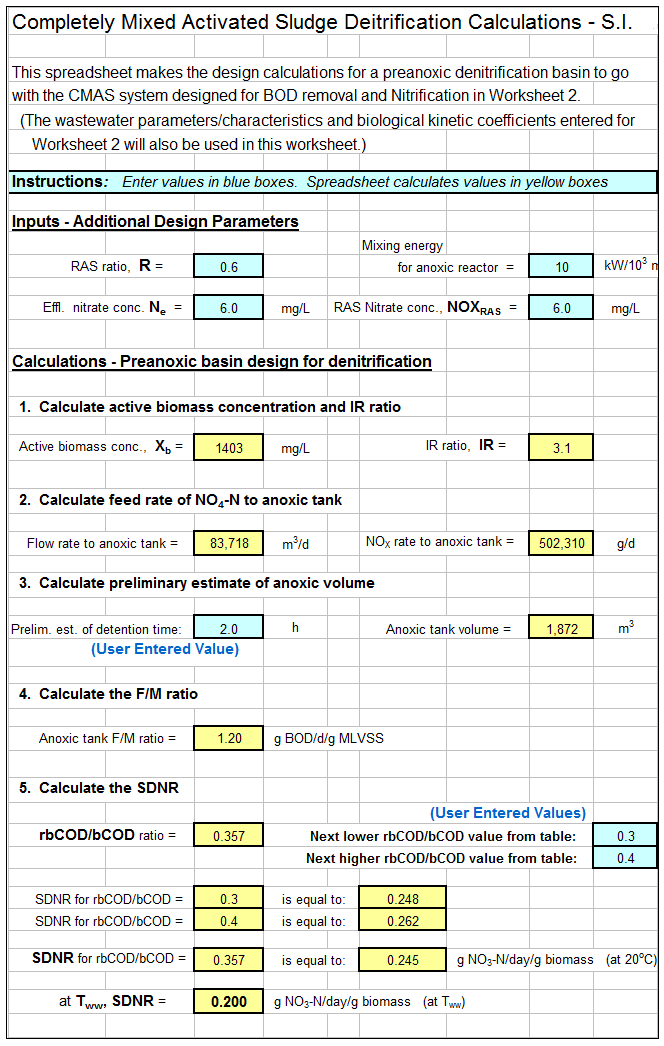

An example EBPR design calculations spreadsheet is partially shown in the image below. This Excel spreadsheet can be used to calculate the required anaerobic tank size, and calculate the phosphorus removal rate and sludge production rate. This Excel spreadsheet, as well as others for wastewater treatment process design calculations, is available in either U.S. or S.I. units for a very reasonable price in our spreadsheet store.

1. Metcalf & Eddy, Inc, (Revised by Tchobanoglous, G, Burton, F.L, Stensel, H.D.), Wastewater Engineering, Treatment and Resource Recovery, 5th Ed., New York, NY, 2014.

2. Bengtson, Harlan H., “EPBR Design Calculations Spreadsheet” an online blog article.