Where to Find an SBR Denitrification Calculations Spreadsheet

To obtain an SBR Denitrification Calculations Spreadsheet, click here to visit our spreadsheet store. This Excel spreadsheet is intended for making design calculations for either pre-anoxic or post-anoxic denitrification in a sequencing batch reactor. You can buy a convenient SBR denitrification calculations spreadsheet for a very reasonable price. It is available in either U.S. units or S.I. units. Read on for background information about sequencing batch reactor denitrification process design calculations.

Background for an SBR Denitrification Calculations Spreadsheet

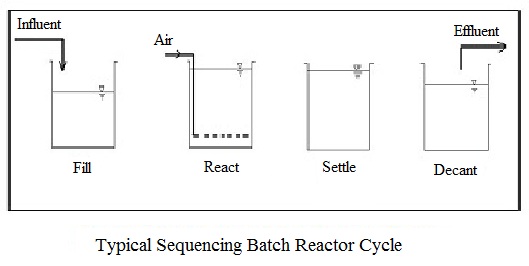

The sequencing batch reactor is a batch type, fill and draw alternative to the continuous flow activated sludge process for biological wastewater treatment, including BOD removal, nitrification and denitrification. The typical components of a sequencing batch reactor operating cycle for BOD removal and nitrification are shown in the diagram below.

At least two tanks are typically used. In that case, the length of the fill period would be equal to the sum of the times for the react, settle and decant periods. Thus one tank would be filling while the other tank was going through the react, settle and decant periods and then the roles would be reversed.

At least two tanks are typically used. In that case, the length of the fill period would be equal to the sum of the times for the react, settle and decant periods. Thus one tank would be filling while the other tank was going through the react, settle and decant periods and then the roles would be reversed.

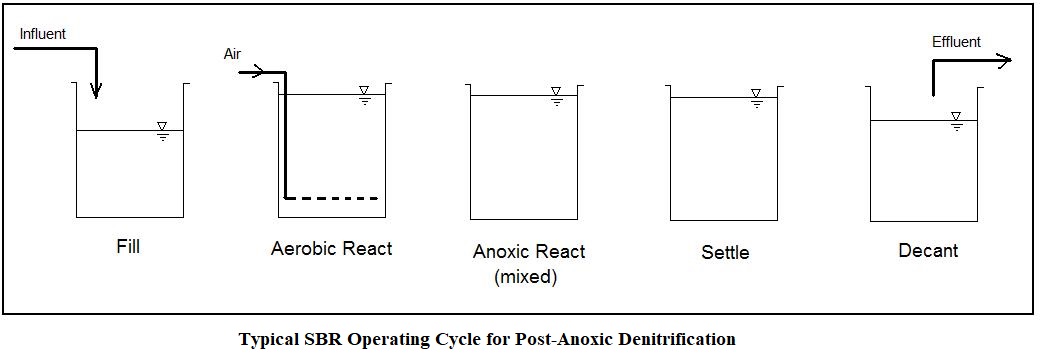

In order to achieve denitrification, an anoxic period must be added. A typical sequencing batch reactor cycle for a post-anoxic denitrification process is shown in the figure below. A mixed anoxic react period is included after the aerobic react period.

For a pre-anoxic denitrification SBR process, some or all of the fill period would be anoxic and there would be no anoxic react period after the aerobic react period.

For a pre-anoxic denitrification SBR process, some or all of the fill period would be anoxic and there would be no anoxic react period after the aerobic react period.

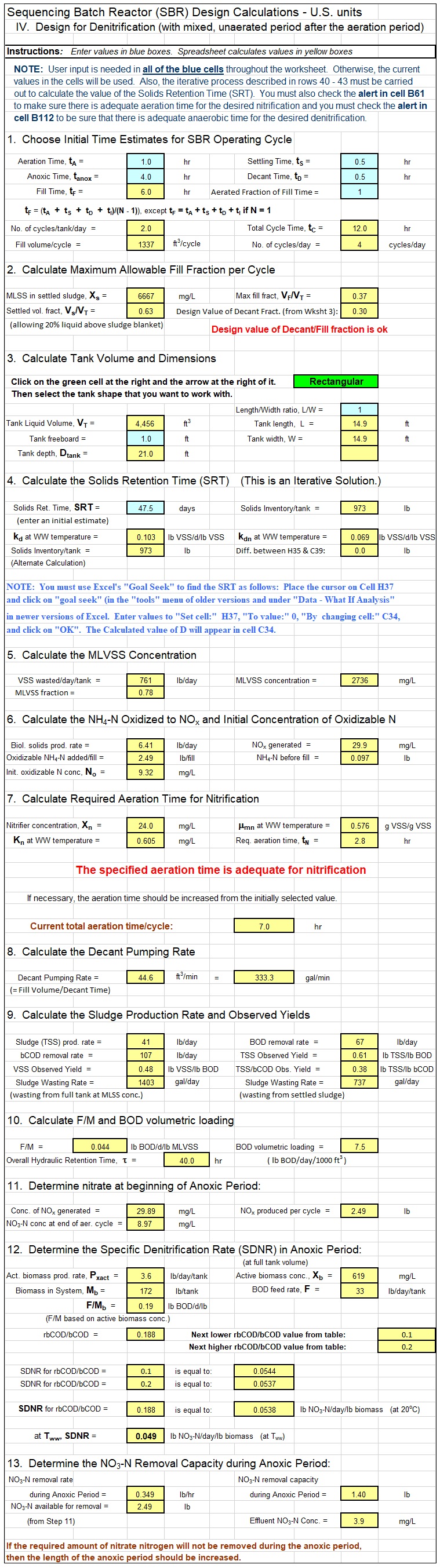

Example SBR Denitrification Calculations Spreadsheet

An example SBR denitrification calculations spreadsheet is partially shown in the image below. This Excel spreadsheet can be used to set the times for the different parts of the SBR operating cycle, calculate the required tank size and check on the adequacy for nitrification and for denitrification. This Excel spreadsheet, as well as others for wastewater treatment process design calculations, is available in either U.S. or S.I. units for a very reasonable price in our spreadsheet store.

References:

1. Metcalf & Eddy, Inc, (Revised by Tchobanoglous, G, Burton, F.L, Stensel, H.D.), Wastewater Engineering, Treatment and Reuse, 4th Ed., New York, NY, 2003.

2. Metcalf & Eddy, Inc, (Revised by Tchobanoglous, G, Burton, F.L, Stensel, H.D.), Wastewater Engineering, Treatment and Resource Recovery, 5th Ed., New York, NY, 2014.

3. Bengtson, Harlan H., “Sequencing Batch Reactor Denitrification Calculations,” an online blog article.