Where to Find a Wastewater Metal Precipitation Spreadsheet

To obtain a Wastewater Metal Preciptitation Spreadsheet, click here to visit our spreadsheet store. This Excel spreadsheet has worksheets for calculating equilibrium values and design values for precipitation of seven metals from wastewater, based on user input values for several parameters . You can buy a convenient metal hydroxide preciptiation spreadsheet for a very reasonable price. It is available in either U.S. units or S.I. units. Read on for background information about a Wastewater Metal Precipitation Spreadsheet.

Background for a Wastewater Metal Precipitation Spreadsheet

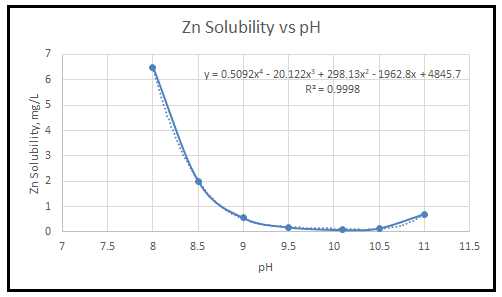

To make calculation for metal hydroxide precipitation from wastewater, data for the solubility of that metal vs pH can be used to obtain an equation for the metal hydroxide solubility as a function of pH. An example graph for zinc solubility vs pH is shown below.

Using an equation like that shown on the graph, equilibrium values can be calculated for effluent metal concentration, chemical usage and solids production. Application of a safety factor will give design values for effluent metal concentration, chemical usage and solids production.

Using an equation like that shown on the graph, equilibrium values can be calculated for effluent metal concentration, chemical usage and solids production. Application of a safety factor will give design values for effluent metal concentration, chemical usage and solids production.

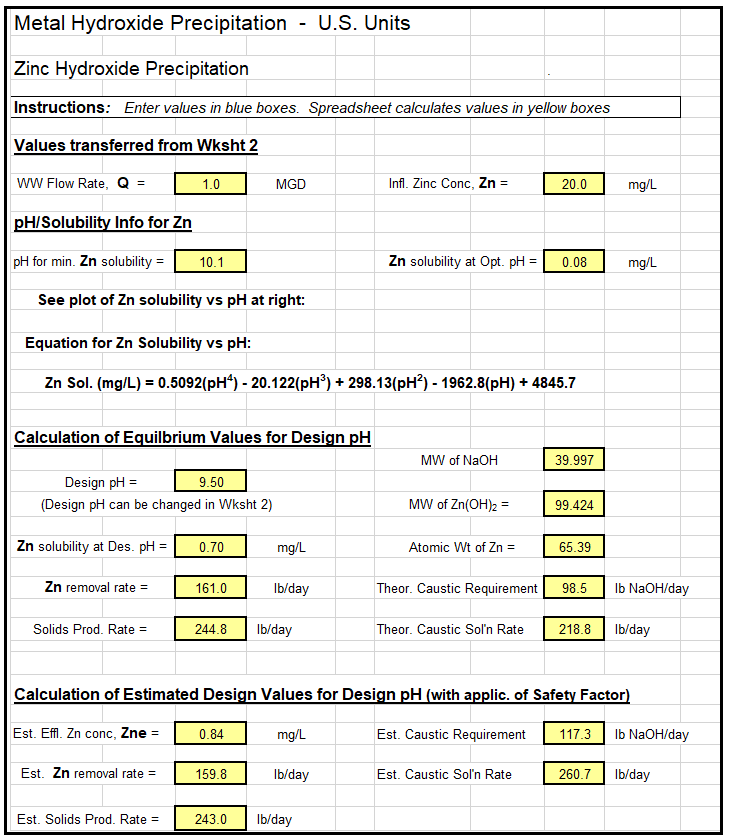

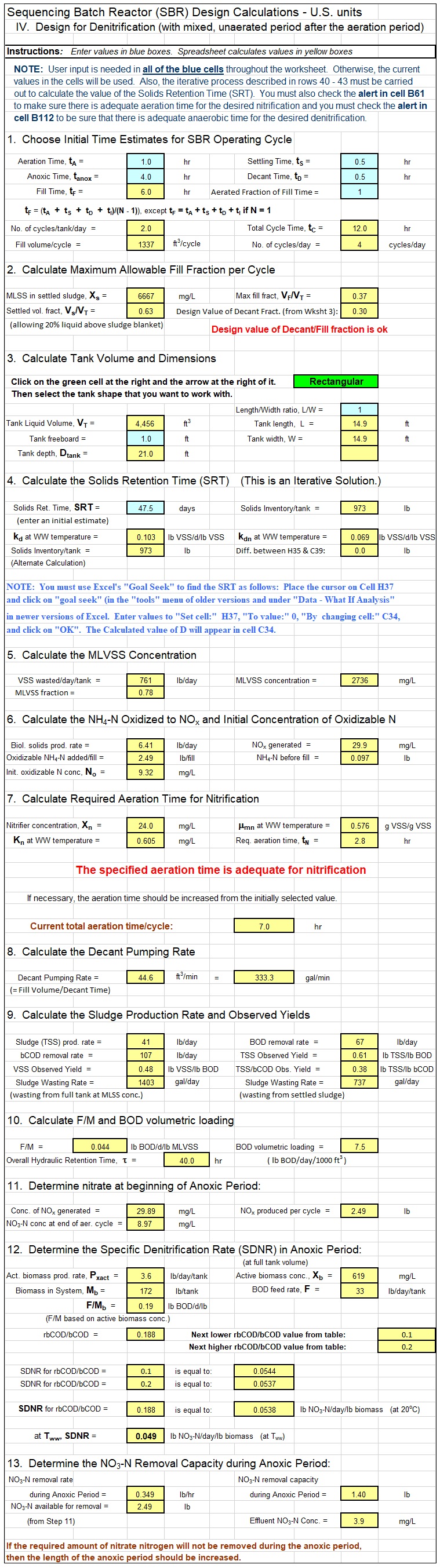

Example Wastewater Metal Precipitation Spreadsheet

An example wastewater metal precipitation spreadsheet is partially shown in the image below. . This Excel spreadsheet can be used to calculate equilibrium and design values for effluent metal concentration, chemical usage and solids production.based on user input values for wastewater flow rate, metal concentrations, design safety factor, and chemical used and its purity, . This Excel spreadsheet, as well as others for water and wastewater treatment calculations, is available in either U.S. or S.I. units for a very reasonable price in our spreadsheet store.

1. Metcalf & Eddy, Inc, (Revised by Tchobanoglous, G, Burton, F.L, Stensel, H.D.), Wastewater Engineering, Treatment and Reuse, 4th Ed., New York, NY, 2003.

2. Metcalf & Eddy, Inc, (Revised by Tchobanoglous, G, Burton, F.L, Stensel, H.D.), Wastewater Engineering, Treatment and Resource Recovery, 5th Ed., New York, NY, 2014.

3. Bengtson, Harlan H., “Wastewater Metal Precipitation Calculations,” an online blog article.