Where to Find an MBBR Wastewater Treatment Design Spreadsheet

To obtain an MBBR wastewater treatment design spreadsheet, click here to visit our spreadsheet store. This Excel spreadsheet can be used for MBBR process design calculations. You can buy a convenient MBBR wastewater treatment design spreadsheet for a very reasonable price. This spreadsheet makes MBBR process design calculations for several configurations for BOD removal and for nitrification. It is available in either U.S. or S.I. units. Read on for information about using an MBBR Wastewater Treatment Design spreadsheet.

Background for MBBR Wastewater Treatment Design Spreadsheet

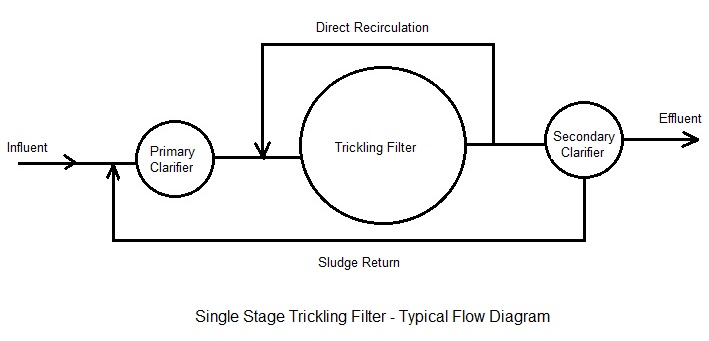

The moving bed biofilm reactor (MBBR) is a relatively recently developed wastewater treatment process. It was developed in the 1990’s, but is now in use in many countries around the world.

The MBBR wastewater treatment process is quite flexible. It is used for domestic and industrial wastewater treatment and can be designed for BOD removal alone or in combination with nitrification. It is used as a single stage process or as a two-stage or three-stage process.

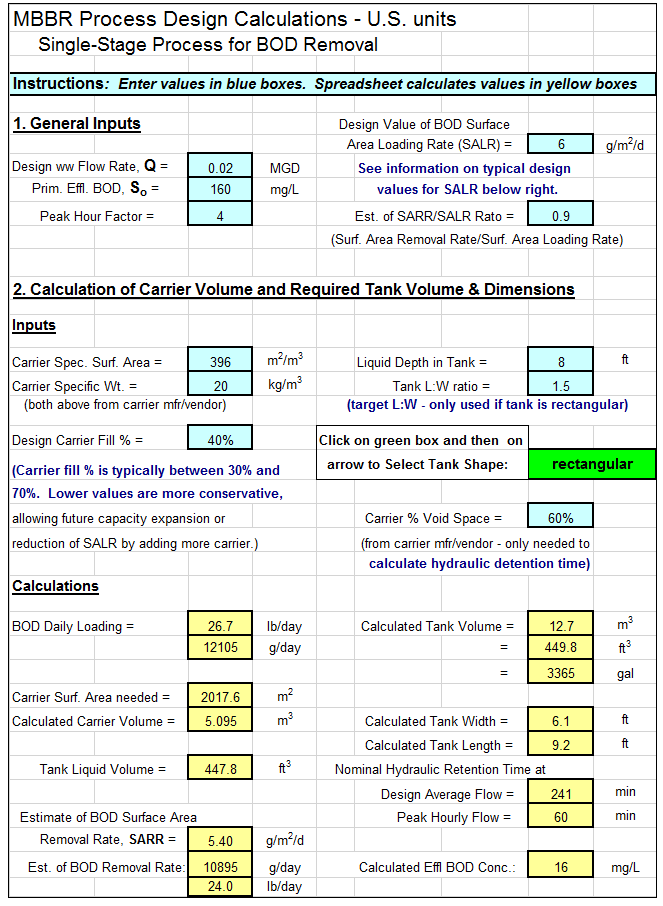

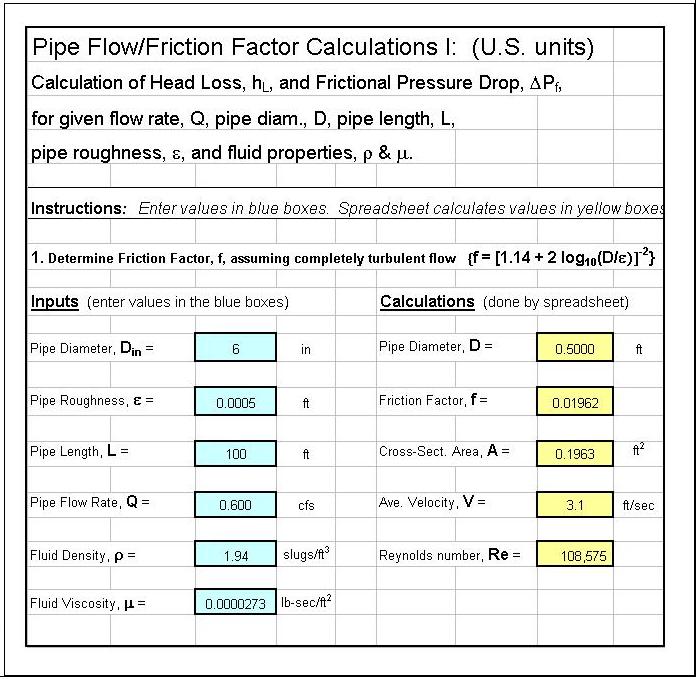

Example MBBR Wastewater Treatment Design Spreadsheet

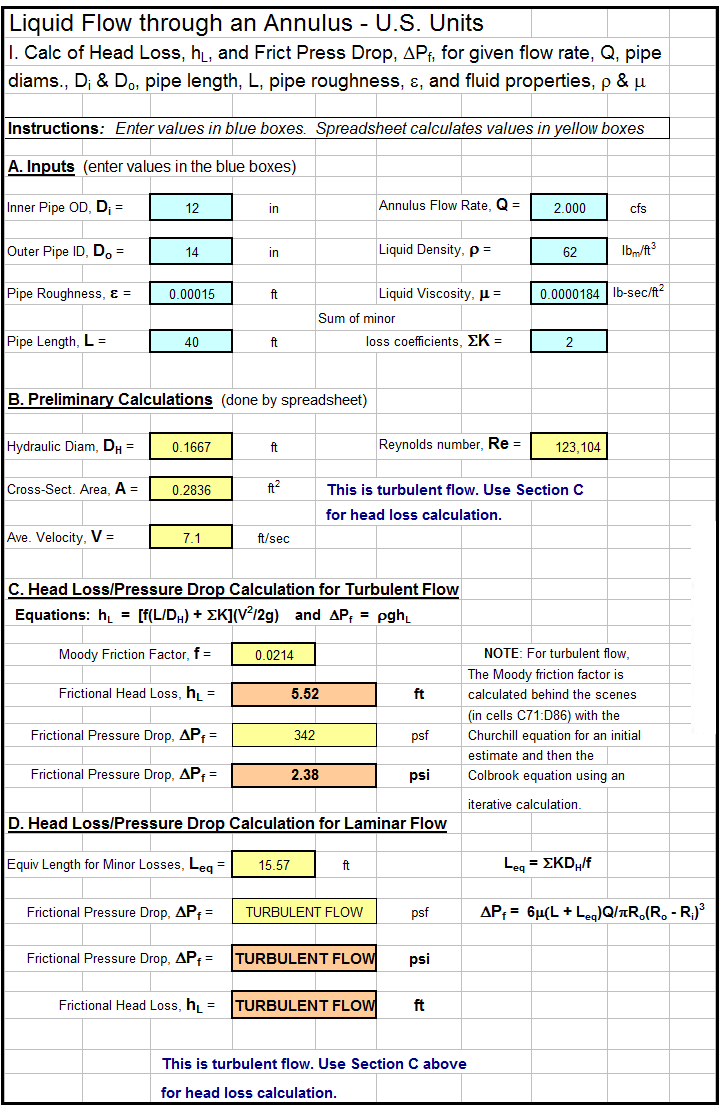

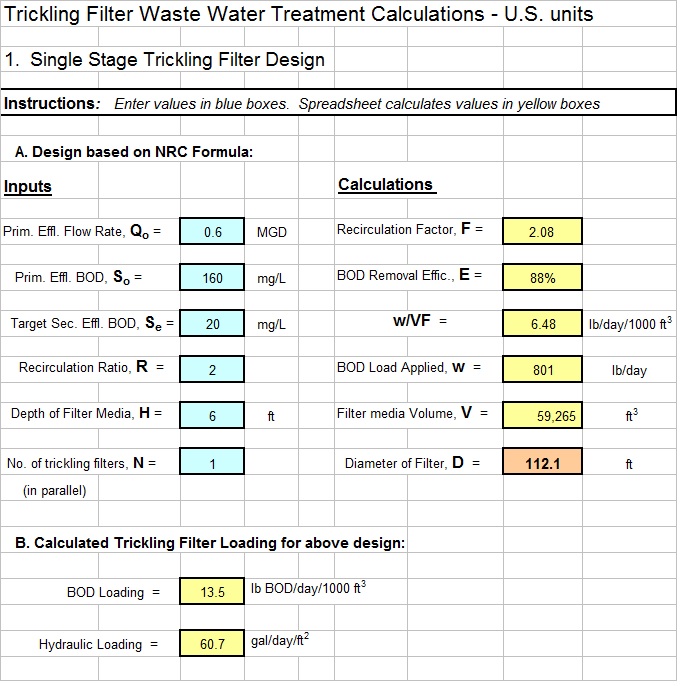

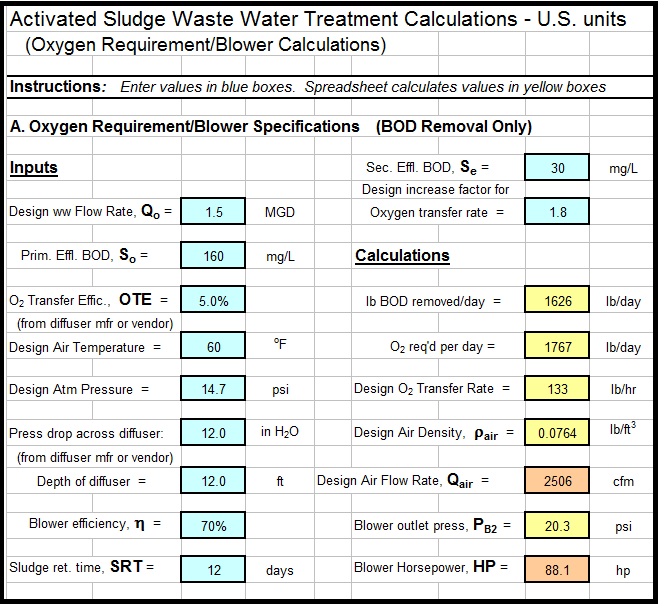

An example MBBR wastewater treatment design spreadsheet is partially shown in the image below. This Excel spreadsheet can be used to calculate the required MBBR tank volume and dimensions, based on user input media information and wastewater design flow and characteristics. This Excel spreadsheet, as well as others for wastewater treatment process design calculations, is available in either U.S. or S.I. units for a very reasonable price in our spreadsheet store.

References:

1. McQuarrie, J.P. and Boltz, J.P., Moving Bed Biofilm Reactor Technology: Process Design and Performance, Water Environment Research, Vol 83, No 6, June 2011.

2. Bengtson, Harlan, “MBBR Process Design Calculations Spreadsheet,” an online blog article

3. Bengtson, Harlan H,, “Spreadsheets for MBBR Process Design Calculations“, Available as an Amazon Kindle e-book and as a paperback.

4. Bengtson, Harlan H., “Biological Wastewater Treatment Process Design Calculations,” available as an Amazon Kindle e-book or as a paperback.

5. Bengtson, Harlan H. “MBBR Wastewater Treatment Processes“, an online course for PDH engineering continuing education credit.