Where to Find a Forced Convection Heat Transfer Coefficient Calculator Spreadsheet

For an Excel spreadsheet to use as a forced convection heat transfer coefficient calculator, click here to visit our spreadsheet store. Read on for information about forced convection heat transfer coefficients and their calculation.

An Excel spreadsheet can be a convenient forced convection heat transfer coefficient calculator. This type of calculation is typically based on a correlation of dimensionless numbers, usually Nusselt number in terms of Reynolds number and Prandtl number. Forced convection occurs with a fluid moving past a solid surface when the fluid and the solid are at different temperatures. Newton’s Law of Cooling [ Q = hA(Ts – Tf) ] is a simple expression for the rate for convective heat transfer. The parameters in Newton’s Law of Cooling are:

- Q is the rate of forced convection heat transfer (Btu/hr – U.S. or W – S.I.)

- Ts is the solid temperature (oF – U.S. or oC – S.I.)

- Tf is the fluid temperature (oF – U.S. or oC – S.I.)

- A is the area of the surface that is in contact with the fluid (ft2 – U.S. or m2 – S.I.)

- h is the convective heat transfer coefficient (Btu/hr-ft2–oF – U.S. or W/m2-K – S.I.)

Dimensionless Numbers for a Forced Convection Heat Transfer Coefficient Calculator

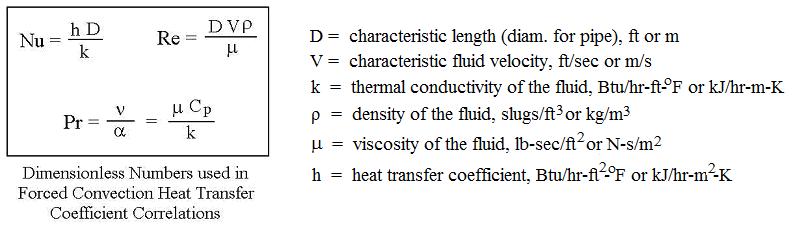

Determining a good estimate for the heat transfer coefficient, h, is often the most difficult part of forced convection heat transfer calculations. The process for estimating the heat transfer coefficient for a particular forced convection application is often through a correlation for Nusselt number (Nu) in terms of Reynolds number (Re) and Prandtl number (Pr). These three dimensionless numbers are defined in the box below, along with the definitions of the parameters that appear in them.

Nusselt Number Correlations for Turbulent Flow Inside a Pipe

The Dittus Boelter equation, which has been around since 1930 (ref #1) has two forms as follows:

Nuo = 0.023 Re0.8Pr0.4 , for ‘heating’ (temperature of wall > temperature of fluid), and

Nuo = 0.026 Re0.8Pr0.3 , for ‘cooling’ (temperature of wall < temperature of fluid).

Subject to: 0.7 < Pr < 120 ; 10,000 < Re < 160,000; L/D > 10 ( L/D > 50 according to some authors). It is a rather simple equation to use, but has a fairly narrow range of acceptable values for Re and Pr.

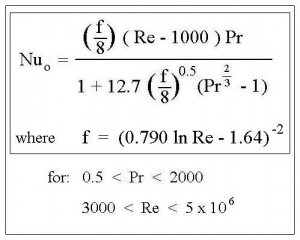

Another correlation (from ref #2) is shown in the box at the right. The range of values for Re and Pr for this correlation are also shown. This correlation can be used for a wider range of values of Re and Pr.

Another correlation (from ref #2) is shown in the box at the right. The range of values for Re and Pr for this correlation are also shown. This correlation can be used for a wider range of values of Re and Pr.

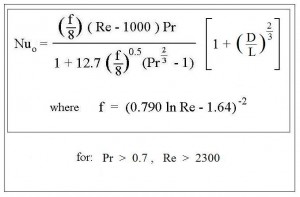

A third correlation is shown in the box at the left below. This correlation, described by Pethukov (ref #3) is only a minor variation of the second correlation shown at the right. This third correlation works for an even wider range of values for Re and Pr.

Excel spreadsheets can be conveniently used as a forced convection heat transfer coefficient calculator with correlations like these or others for configurations like laminar pipe flow, flow inside a circular annulus, flow outside a cylinder, flow past a bank of tubes, or flow in a noncircular cylinder, because the equations can be programmed into the spreadsheet using Excel formulas. For free download of an Excel spreadsheet for calculating forced convection heat transfer coefficients for laminar pipe flow, and low cost spreadsheets for all of the other configurations mentioned above, click here to visit our spreadsheet store.

Excel spreadsheets can be conveniently used as a forced convection heat transfer coefficient calculator with correlations like these or others for configurations like laminar pipe flow, flow inside a circular annulus, flow outside a cylinder, flow past a bank of tubes, or flow in a noncircular cylinder, because the equations can be programmed into the spreadsheet using Excel formulas. For free download of an Excel spreadsheet for calculating forced convection heat transfer coefficients for laminar pipe flow, and low cost spreadsheets for all of the other configurations mentioned above, click here to visit our spreadsheet store.

References

1. Dittus, P.W. and Boelter, L.M., Univ. Calif. Pub. Eng., Vol. 1, No. 13, pp 443-461 (reprinted in Int. Comm. Heat Mass Transfer, Vol. 12, pp 3-22 (1985).

2. egr.msu.edu

3. Petukhov, B.S., “Heat transfer and friction in turbulent pipe flow with variable physical properties,” Adv. Heat Transfer 6, 503-565 (1970).